WINERY FAMILY WEISS owns a winery in Gols in the wine-growing area Neusiedlersee. For generations, they have been cultivating about 7 ha of vineyards. They proudly produce wines that are typical for Austria, using traditional varieties like Zweigelt, but also St. Laurent, Blaufränkisch, Grauburgunder. With Markus Weiss in charge of the cellar, this winery knows how to harmonize tradition and the modern era. Next to delicious quality wines, they produce Native Grape, a unique non-alcoholic fermented Grape Juice, served in gastronomic restaurants all over Europe.

The challenge

With a growing demand for customization of the packaging and labeling of their products, Winery Family Weiss wanted to have more flexibility and control over the identification process, while keeping high-quality standards. At the same time, the Family Weiss has a strong focus on producing their wines in a biological and sustainable way. Using preprinted labels created several conflicts with the strategy and service they want to offer their customers:

- long lead times (external label design, approval process, …)

- too high minimum order quantities, resulting in lots of waste and place consuming label stocks

- too expensive for small customized productions

Next to this, they wanted to be able to customize a second label, for the back of the bottle, with variable information. That label is made of natural and fully recyclable components,, appealing to nature when holding the bottle in the palm of your hand. In the end, consuming a quality wine is emotional…

The solution

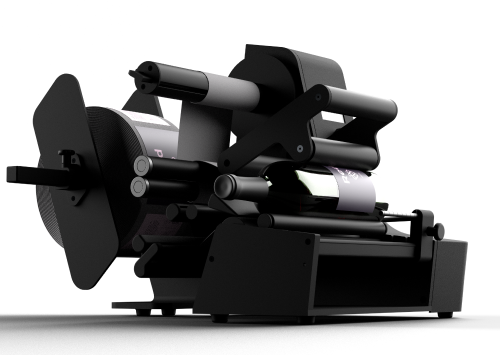

After the evaluation of different alternatives and on the advice of their solution provider, BSR, the winery decided to invest in an Epson Color label printer together with 2 units of the Labelmate UNI-CAT, one working as an unwinder to feed the labels into the printer, one working as a rewinder to rewind the labels after the printing process into straight and tight new finished label rolls. Printed label rolls are then placed in the label applicator, part of the fully automatic filling station. For small batch sizes, the label roll is placed in an off-line semi-automatic applicator.

Benefits

- The in-house printing of labels helps to achieve their sustainability goals like reducing waste material to a minimum.

- Offering a customization service to their customers, even for small quantities, becomes now affordable and easy to implement. Lead times up to 2 weeks for a custom label will become a distant memory.

- With the UNI-CAT Label Rewinder/Unwinder, the solution has the autonomy to print more than 3000 bottle labels allowing an operator to leave after pushing the start button. Circa 1 hour later, a fully printed label roll can be collected.

“We have chosen the Labelmate rewinder not only because we know that it works perfectly with our colour printer, but also because of its high roll capacity and the industrial build quality of the device. “ – Markus Weiss